Alloy R&D has resulted in a material that combines the affordability of 310 stainless steel with the high temperature properties of more expensive higher nickel alloys, like alloy 600. Be it for your muffle belt conveyor or heat treating trays, this Technical Tuesday installment by Hugh Thompson, applications engineer of Rolled Alloys, will explore the strengths of this alloy variety to determine its best application.

This informative piece was first released in Heat Treat Today’s July 2025 Super Brands print edition.

Increasing nickel prices initiated the development of RA 253 MA®, a versatile alloy used in various thermal applications for equipment construction. With low chromium (Cr) and nickel (Ni) levels, this alloy provides a cost-effective alternative to other pricier nickel-based materials. With microalloying control, it is priced alongside 310 stainless steel while offering high strength properties similar to the more costly 600-series alloys.

Chemically similar to 309 stainless steel, the alloy offers significantly higher creep resistance and rupture strength than 310. Its benefits include:

- Oxidation resistance up to 2000°F

(1090°C) - Significant hot tensile strength

comparable to that of the 600-series alloys - Noteworthy creep and rupture properties

This lean austenitic stainless steel uses cerium and silicon to create a very adhesive oxide, resulting in excellent oxidation resistance. The combination of nitrogen and carbon provides creep-rupture strength double that of 310 and 309 stainless steel at 1600°F (870°C).

Chemistry

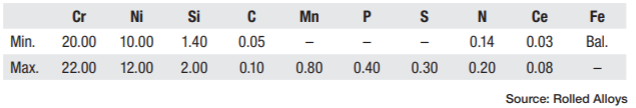

RA 253 MA has a specified chemistry, as indicated in Table A.

High Temperature Properties

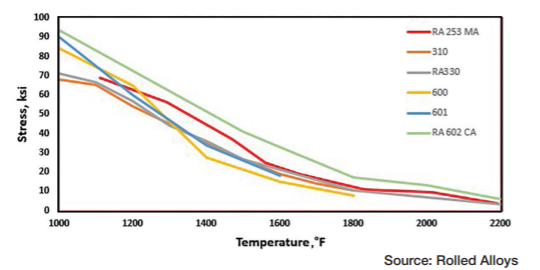

Figure 1 shows the hot tensile strengths of different materials. RA 253 MA can be seen to have higher hot tensile properties than alloy 600, 310 stainless, and RA330® but lower than RA 602 CA®. It’s worth noting that while its hot tensile strength is reported up to 2200°F (1200°C), practical use is limited to 2000°F (1090°C) in oxidizing environments due to a loss of oxidation resistance at this temperature.

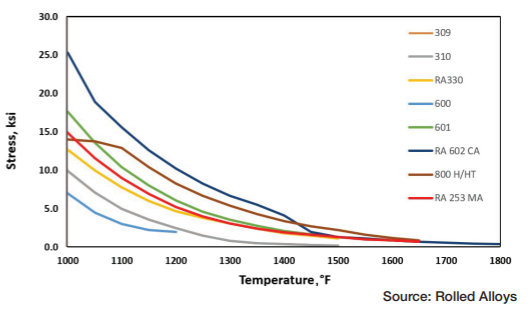

Figure 2 displays the allowable design stresses for pressure vessel plates according to Section II-D of the ASME 2023 (2024 revision) code. One can see that the allowable stresses for RA 253 MA are higher than those for 310 stainless and RA330 but not as high as alloy 601. ASME allows design stresses for this alloy up to 1650°F (900°C). However, RA 253 MA is utilized at higher temperatures for various applications because this temperature limit is only for pressure vessels.

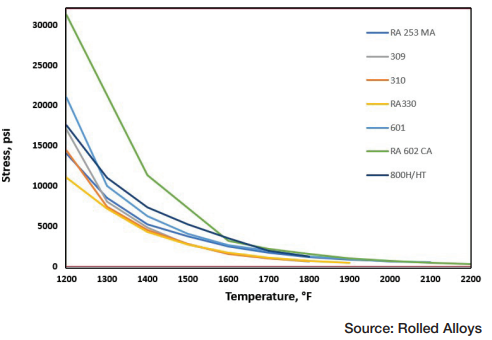

Figure 3 displays the actual 10,000-hour rupture strengths of different high temperature alloys. The data reveal that RA 253 MA exhibits high creep and rupture stress values comparable to alloy 601 and RA 602 CA, and it surpasses RA330; this would also surpass alloy 600.

In Figure 4, data are presented for the minimum creep rate of 0.0001% per hour. Creep refers to the rate at which metal stretches, and it is usually measured in percentage per hour. There is a phase where the creep rate remains relatively constant, known as the secondary creep rate. This rate is a key factor in designing for high temperatures. It’s important to consider that metal will creep even under light loads, as the effects of creep can be observed in material with no load other than its own weight. Therefore, in practical applications, a creep criterion is utilized for design purposes.